Isolated Phase Bus (IPB)

8

8.1 Introduction

With the increase in the demand for electrical power, it was realized that it is more economical to generate power with a large unit, than with several small units that could be connected in parallel. Today many coal-fired and hydroelectric power plants with unit ratings of 800 MW and nuclear power plants with unit ratings of 1500 MW are in operation. The terminal voltage of a large alternator has reached 36 kV. With the proportional increase in the cost of the power plant, it became imperative that all components of the generating system of the power plant should be extremely reliable as even a minor disruption would incur a very heavy revenue loss. The generator connection is one of the key components that need to be extremely reliable.

An increase in the unit rating implied an increase in the rated current of the generator and fault levels. A reliable generator connection had to, therefore, cater to the following challenges:

- Carry large current within the thermal constraints

- Withstand massive electrodynamic forces during fault

- Contain the magnetic field in a confined area

- Eliminate phase to phase fault

- Minimize the probability of a ground fault.

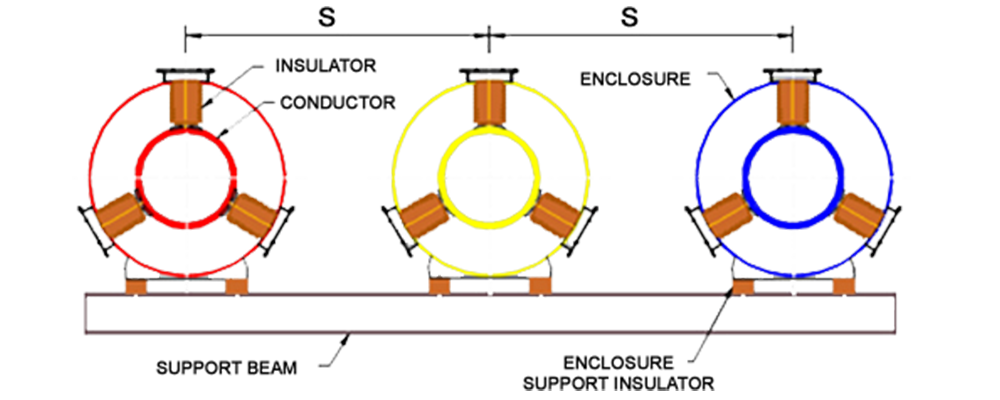

The development of isolated phase bus to meet these demands can be traced back to 1930 in the US and subsequently in Europe. It was realized that the only way to meet the demand was to enclose each phase conductor in a separate conducting enclosure. The earliest configurations were a modification of the segregated phase bus where a conductor (2 channels in box formation) was enclosed in a square, Aluminium enclosure. (There are stations where the generator connections have been made with open conductors with support and tie insulators at minimal spans).

Typical Arrangement Of 3∅ Isolated Phase Busbar (Figure – 8.1)